What is SHS steel?

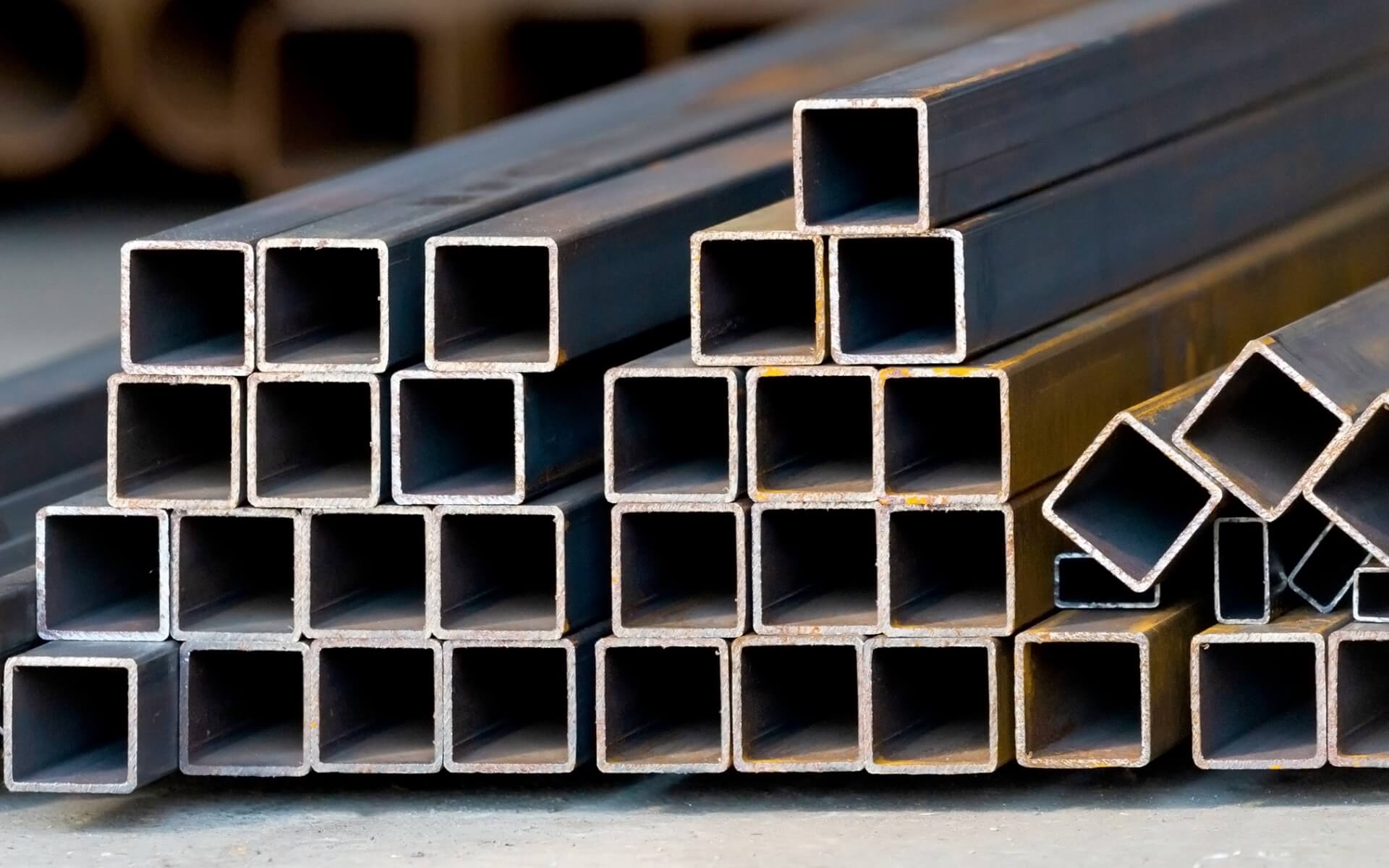

SHS steel is a popular type of structural steel tube with four equal sides that gives it a symmetrical appearance. SHS stands for Square Hollow Section. It has a flat surface that is easy for joining and welding, with minimal edge preparation required.

How is SHS made?

During the manufacturing process of SHS, a flat steel plate is gradually changed to round shape with the edges ready to weld. The edges are then welded together to form a round tube called the mother tube. This mother tube then goes through a series of shaping processes into the final square shape.

What is SHS used for?

SHS is used in structural, industrial, mechanical and construction applications where a balance between strength, functionality and aesthetic appeal is required. They are used to constructing frames, gates, and posts. Its uses are similar to the uses of RHS and is generally available in the same thicknesses as RHS. Galvanised SHS or Square Hollow Section steel is extremely durable and prevents cracks from occurring.

Benefits of using SHS and RHS in construction

- The tubular form of SHS and RHS gives a better strength to weight ratio compared to other types of steel, concrete or timber.

- Better strength to weight ratio helps in building more aesthetically pleasing, airey and lightweight structures with reduced material usage and greater spans.

- Since there is less usage of material, there is less wastage and even if it is there, it can be fully recycled.

- Less construction times which means less impact on surrounding communities.

- Lightweight nature of SHS enables extensions to be built to existing buildings without overloading their foundations.