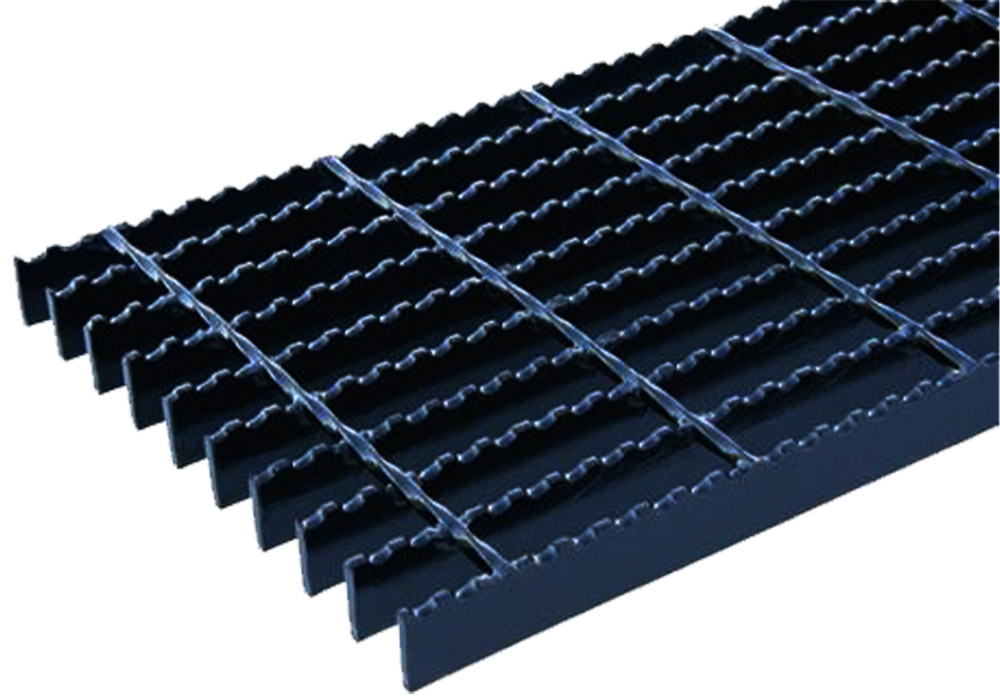

Steel bar grating has two surface type: serrated surface and smooth surface. Serrated steel grating is made of serrated steel bars, which can be low carbon steel bars, aluminum steel bars and stainless steel bars. The serrated steel bars are welded, press-locked, swage-locked or connected by rivets to form different types of steel grating.

Classification of serrated steel grating

The serrated steel grating has various different types, according to the different fabrications and materials, the serrated steel grating can be divided into different types. The different types can be applied in different applications and supply more choice for customers.

Fabrications of serrated steel grating- Welded serrated steel grating.

- Swage-locked serrated steel grating.

- Press-locked serrated steel grating.

- Riveted serrated steel grating.

- Low carbon serrated steel grating.

- Aluminum serrated steel grating.

- Stainless steel serrated steel grating.

-

Anti-slip

The raised surface supplies excellent slip resistance performance, which can be used in the wet and slippy places.

-

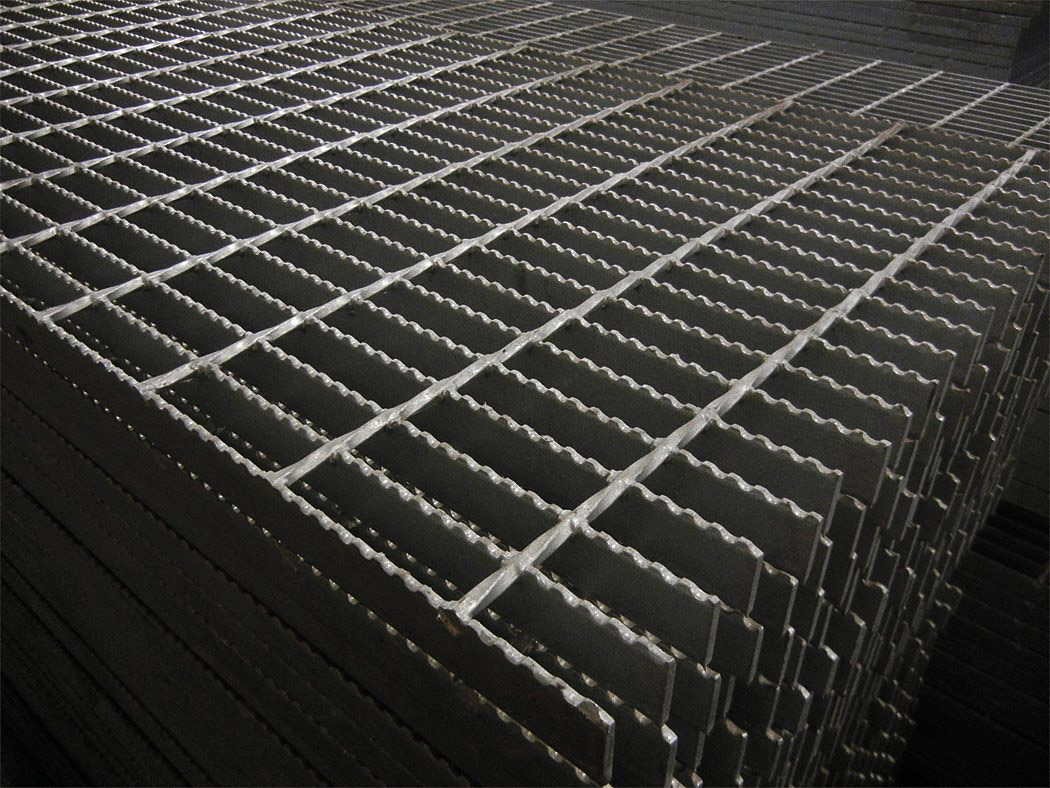

Corrosion resistance

Galvanized surface treatment supplies good corrosion resistance performance, which ensure the long service life.

-

Acid and alkali resistance

Stainless steel serrated steel grating has excellent chemical stability, which can be used in the salty and other chemical corrosive environments.

-

Protect safe

The serrated surface can protect pedestrian from slipping down and secure the safe of pedestrians.

- Serrated steel grating features outstanding slip resistance, it is widely used in the environments filled with water, oil and other elements may cause slipping.

- It is widely used as stair tread grating to secure pedestrians safely go up and down.

- The serrated steel grating is widely used as platform walkway grating in pedestrian street, balcony and factories for anti-slip application./li>

- The serrated steel grating can be installed on the drainage and trench as drainage trench cover to drain water and keep ground dry.